Manufacturer of 3536 Brushless Motor - High Torque Automotive Electric BLDC Motor-W5795 – Retek

Manufacturer of 3536 Brushless Motor - High Torque Automotive Electric BLDC Motor-W5795 – Retek Detail:

Product Introduction

This product is a compact high efficient brushless DC motor, magnet ingredient consist of NdFeB(Neodymium Ferrum Boron) and high standard magnets imported from Japan which greatly enhance the efficiency comparing to others available motors in the market. Top quality bearing with strict end play greatly improve the precision performance.

Comparing to brushed dc motors, it has great advantages as below:

● High performance and efficiency – BLDCs are broadly more efficient than their brushed counterparts. They use electronic capabilities, allowing for fast and precise control of the speed and position of a motor.

● Durability – There are fewer moving parts that control brushless motors than PMDC, making them more resistant to wear and impact. They’re not prone to burnout due to sparking that brushed motors often encounter, making their lifespan significantly better.

● Low noise – BLDC motors operate more quietly because they don’t have brushes that constantly make contact with other components.

General Specification

● Voltage Range: 12VDC, 24VDC, 36VDC, 48VDC.

● Output Power: 15~300 watts.

● Duty: S1, S2.

● Speed Range: up to 6,000 rpm.

● Operational Temperature: -20°C to +40°C.

● Insulation Grade: Class B, Class F.

● Bearing Type: durable brand ball bearings.

● Optional shaft material: #45 Steel, Stainless Steel, Cr40.

● Optional housing surface treatment: Powder Coated, Electroplating, Anodizing.

● Housing Type: IP67, IP68.

● RoHS and Reach Compliant.

Application

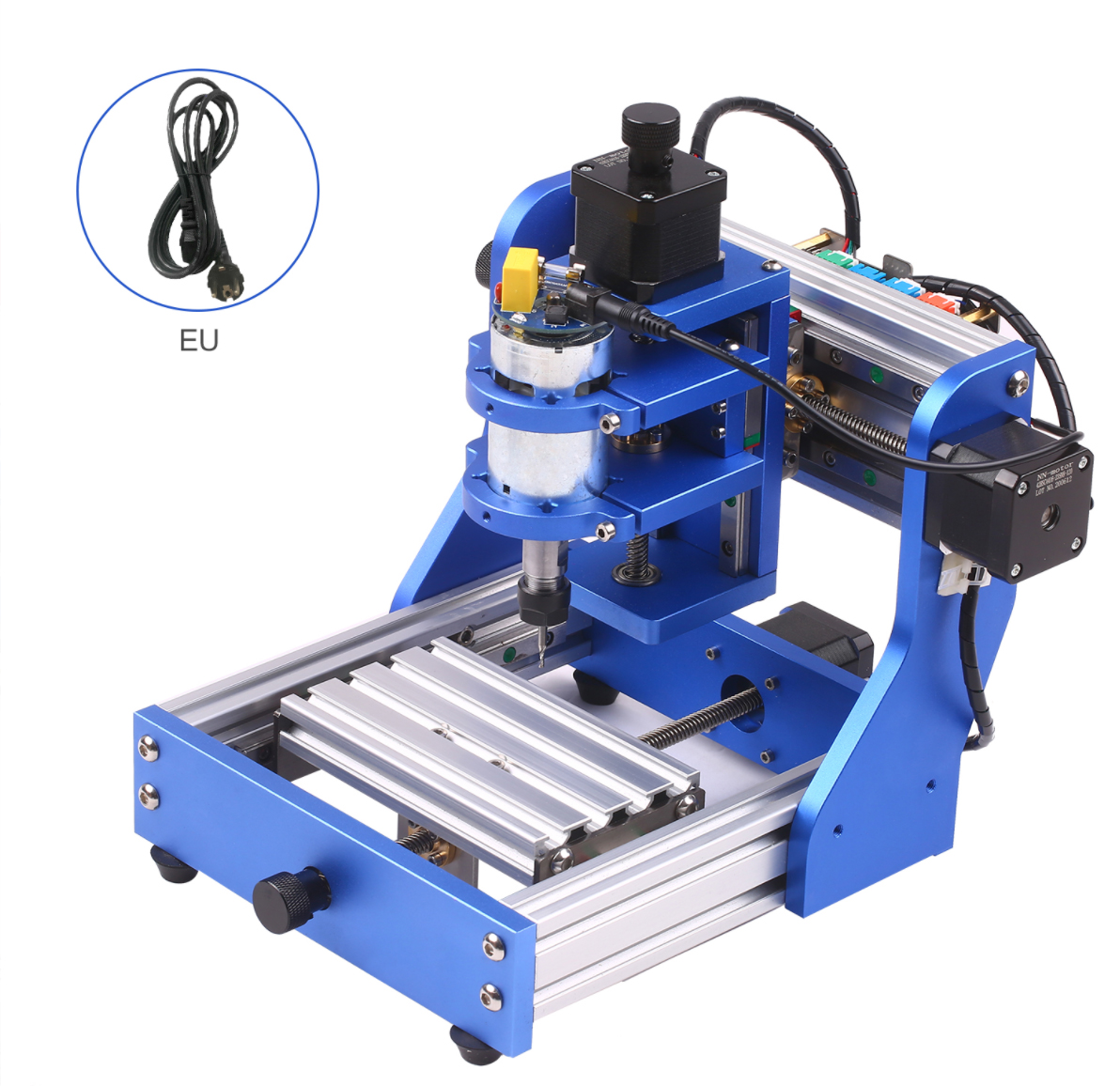

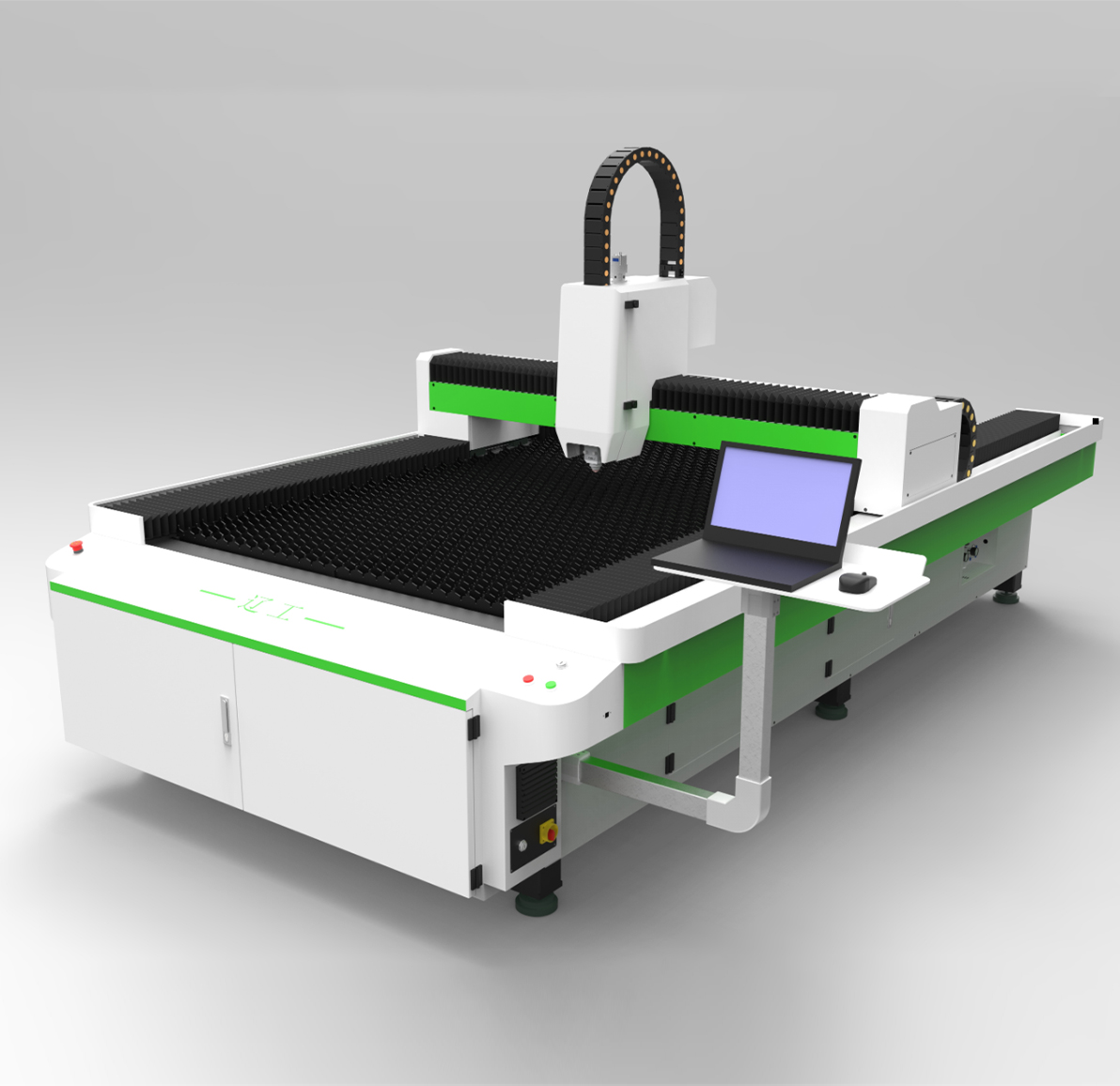

CUTTING MACHINES, DISPENSER MACHINES, PRINTER, PAPER COUNTING MACHINES, ATM MACHINES AND ETC.

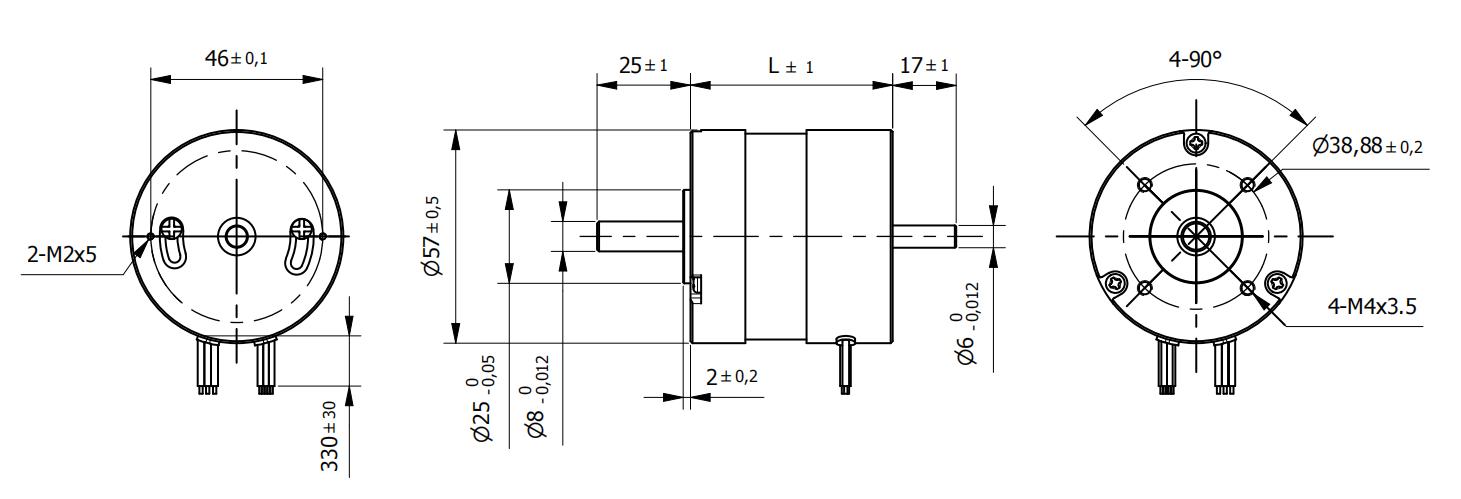

Dimension

Typical Performances

|

Items |

Unit |

Model |

||||

|

W5737 |

W5747 |

W5767 |

W5787 |

W57107 |

||

|

Number Of Phase |

Phase |

3 |

||||

|

Number of Poles |

Poles |

4 |

||||

|

Rated Voltage |

VDC |

36 |

||||

|

Rated Speed |

RPM |

4000 |

||||

|

Rated Torque |

N.m |

0.055 |

0.11 |

0.22 |

0.33 |

0.44 |

|

Rated Current |

AMPs |

1.2 |

2 |

3.6 |

5.3 |

6.8 |

|

Rated Power |

W |

23 |

46 |

92 |

138 |

184 |

|

Peak Torque |

N.m |

0.16 |

0.33 |

0.66 |

1 |

1.32 |

|

Peak Current |

AMPs |

3.5 |

6.8 |

11.5 |

15.5 |

20.5 |

|

Back E.M.F |

V/Krpm |

7.8 |

7.7 |

7.4 |

7.3 |

7.1 |

|

Torque Constant |

N.m/A |

0.074 |

0.073 |

0.07 |

0.07 |

0.068 |

|

Rotor Interia |

g.cm2 |

30 |

75 |

119 |

173 |

230 |

|

Body Length |

mm |

37 |

47 |

67 |

87 |

107 |

|

Weight |

kg |

0.33 |

0.44 |

0.75 |

1 |

1.25 |

|

Sensor |

Honeywell |

|||||

|

Insulation Class |

B |

|||||

|

Degree of Protection |

IP30 |

|||||

|

Storage Temperature |

-25~+70℃ |

|||||

|

Operating Temperature |

-15~+50℃ |

|||||

|

Working Humidity |

<85%RH |

|||||

|

Working Environment |

No direct sunlight, non-corrosive gas,oil mist, no dust |

|||||

|

Altitude |

<1000m |

|||||

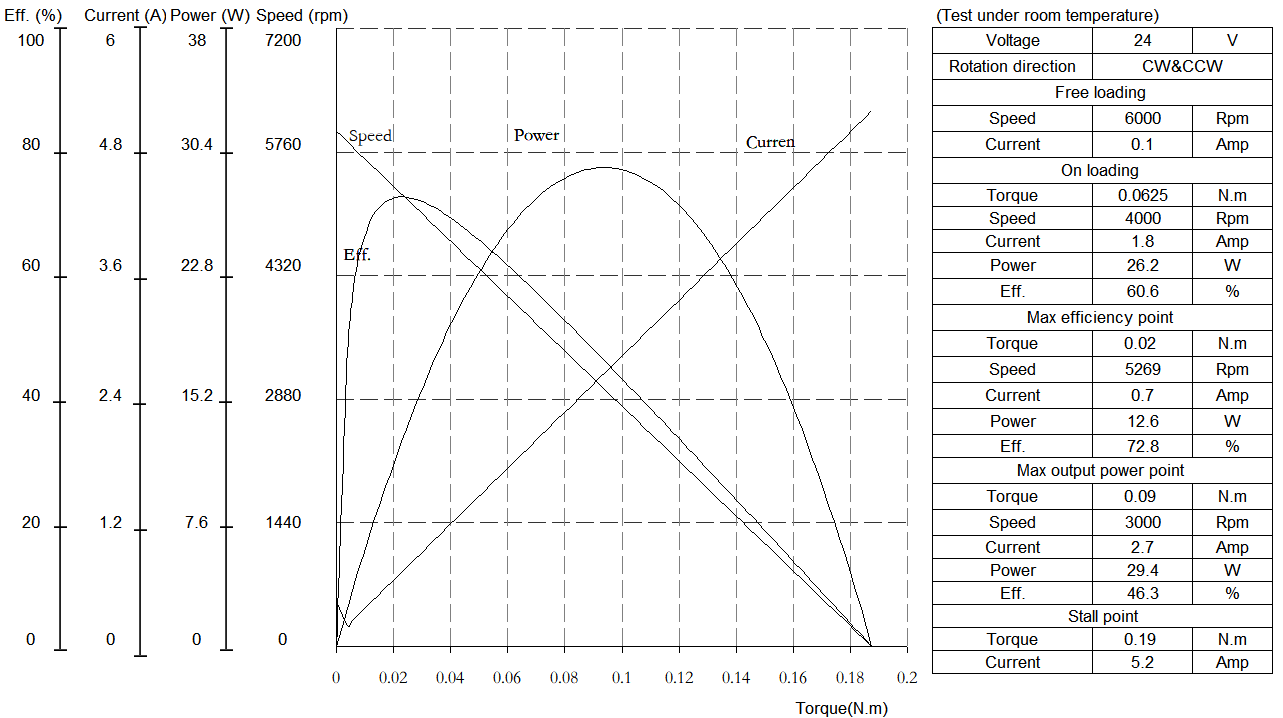

Typical Curve @36VDC

FAQ

1. What are your prices?

Our prices are subject to specification depending on technical requirements. We will make offer we clearly understand your working condition and technical requirements.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. Normally 1000PCS, however we also accept the custom made order with smaller quantity with higher expense.

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 14 days. For mass production, the lead time is 30~45 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance before shipment.

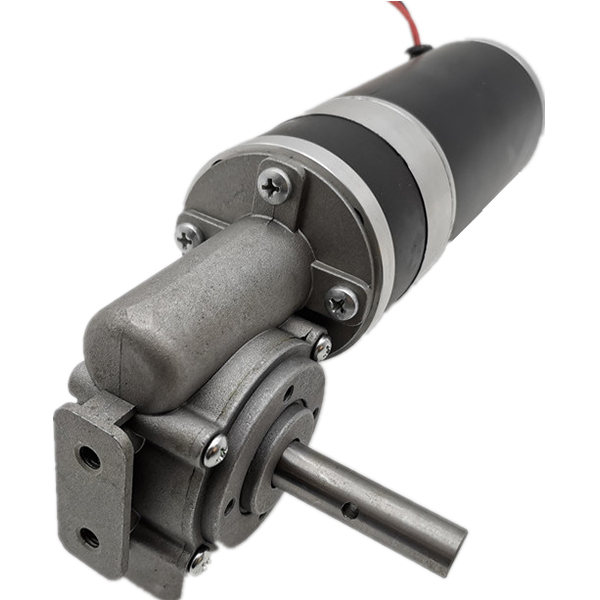

Product detail pictures:

Related Product Guide:

We have advanced equipment. Our products are exported to the USA, the UK and so on, enjoying a good reputation among customers for Manufacturer of 3536 Brushless Motor - High Torque Automotive Electric BLDC Motor-W5795 – Retek , The product will supply to all over the world, such as: Iran, Cyprus, Austria, We'd like to invite customers from abroad to discuss business with us. We can present our clients with high quality products and excellent service. We're sure that we'll have good cooperative relationships and make a brilliant future for both parties.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!